![]() Recently, Fred Foster, owner of Technical Training Professionals, and fellow 3D-animated training proponent, sat down with us to discuss the finer points of using computer-based courses for technical training, and give us his perspective on the future of manufacturing training.

Recently, Fred Foster, owner of Technical Training Professionals, and fellow 3D-animated training proponent, sat down with us to discuss the finer points of using computer-based courses for technical training, and give us his perspective on the future of manufacturing training.

Read below to see what Fred had to say about manufacturing training in general and the use of 3D graphics in particular.

Once you’ve finished, use the comments section below to include your own predictions for the future of manufacturing training, or do share your thoughts about 3D animation and training, or even stuff like virtual reality (VR) and augmented reality (AR) for manufacturing training

- Learning Management Systems

- Online Manufacturing & Maintenance Training Courses

- Workplace Scheduling Software

- Safety Management Software

- Mobile Training Apps

The Future of Manufacturing Training Is Here Today

We’ll discuss the use of 3D training in manufacturing with Fred Foster in this interview. Before you begin reading, take a quick look at this overview video, which includes just a few highlights from our manufacturing & industrial maintenance online training library (which, of course, uses 3D-rendered images).

For some additional information, you might also check out:

- How we build 3D-animated online manufacturing training courses

- 10 amazing things you can do with 3D animation in an online training course

And now, let’s get to our talk with Fred.

How long have you been involved in manufacturing training?

I’ve been in this business for fifteen years. I formed my company, Technical Training Professionals, in 2003, but I had worked for other companies before then.

And what’s your approach to training in manufacturing?

Visual presentation of technical information is our focus. Whether it’s explaining design, Flow paths, troubleshooting — you just can’t beat 3D imaging for presenting that material. With 3D animations we can relay technical subjects ten times faster and make it much more interesting to the people in today’s workforce.

One of the products we develop is what we call a 3D PDF, and that 3D PDF is the 3D model broken out into systems. So, if you want to find where a valve is, it will show you. You can query and it will show you where the valve is. And it could be on a thirteen story boiler and you could say “show me the superheat system,” and it will just show you the superheat system. And then you can click on a valve and it will isolate it and let you manipulate it in 3D.

“The newer population doesn’t sit and read a six-inch thick manual. They won’t do it.”

Control room guys love that because they can show the maintenance workers where something’s at. Or if a guy is going to go out and crank on a valve, they can say, “this is MSCV 2950, go cut off the steam,” and the operator will say, “Where the hell’s that at?” And he can point to it: “It’s on the twelfth floor right over here.” It’s pretty cool.

The newer population doesn’t sit and read a six-inch thick manual. They won’t do it. But they’ll look at these animations to figure out how something works and then they’ll go study what they need to or what they don’t understand. It’s a great icebreaker for somebody who’s learning a new complicated machine and then they’ll go deeper if they need to, but they will not just sit and read a six-inch manual. They won’t do it.

Are the people that are actually taking the manufacturing training pretty receptive to the 3D style?

Yes. Even the more experienced people, because they have a hard time explaining it to the younger people. They’ll use terms and expressions and the young guys don’t know what they’re talking about. They’ll talk about something like, “the stem-valve leak off line.” Well, what the heck is that? And they show them a 2D drawing and they say “it’s right here,” and they’re like, “oh…” But if we fly around the valve in a 3D video and say “okay, here’s the stem leak off. It pulls steam off from here and drains it down to here and that has to be removed in the sixth step….” There’s really no comparison.

Even a senior guy at say, a gas plant, maybe he’s coming from a coal plant that’s been shut down. He’s mechanically astute, he just doesn’t know combined gas plant versus coal-fire plants. They’re different. So it’s still valuable for cross training. These older people—they don’t want to sit and read a manual either, but they’ll watch a five-minute video that shows how something works.

I can’t tell you the number of times I’ve had guys who have worked on machines for years and they’ll say, “You know? I’ve worked on this machine for fifteen years and I never really understood how that gear drive works.” And I’ll have people that will look at something and they’ll say, “Okay, I’ve got it. I’ve got it. I see how it works. I got it.” And it’s very empowering to them because they don’t want to struggle to understand something. Number one, it makes them feel incompetent, and number two, it’s dangerous because they don’t really know what they’re doing because they don’t understand how it works. A lot of accidents are caused not by carelessness, but more by a lack of understanding of how the device works.

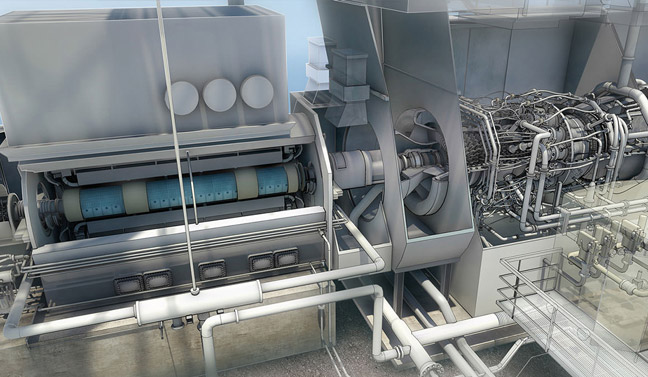

Cutaway of a GE7FA gas turbine and generator

So, you cover occupational safety in addition to, say, principles of operation?

Yes, we include safety in everything. We do what are called “site overviews”, where we’ll overview the whole site for a safety video and talk about tagging, but we’ll also talk about where the hazardous chemicals are. We’ll talk about where the electrical high-voltage is. We’ll talk about egress routes. We’ll talk about where tagging is performed. But we also go through and explain: “This is a combustion turbine. It runs on gas, gas is fed here, and it produces mechanical energy which turns to the generator which makes electricity, but the exhaust gases go to this recovery boiler”. We’ll spend about a minute or two explaining the major components and flying around and showing them, so if these guys watched this for seven to ten minutes, you’ve covered a few safety subjects, but you’ve also explained how the plant works a little bit to them.

So are people using this training for site orientations? Onboarding?

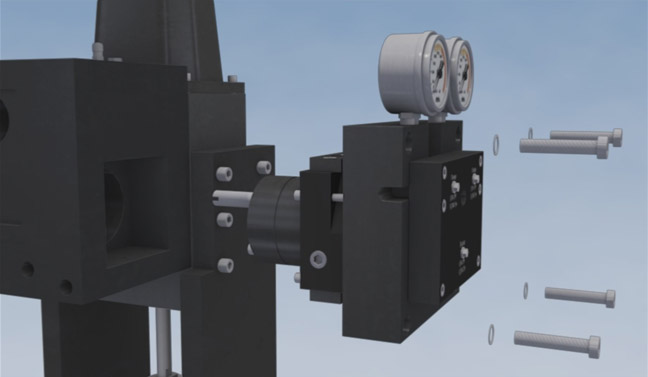

Well, that and we’re getting a lot more maintenance requests. Maintenance people want to see how the machine works, just like an operator. Now, they may not be as interested in all the start up steps, but they’re definitely interested in design and flow paths. So we have maintenance courses on all sorts of things, whether it’s a hydraulic actuator or a boiler-feed pump or a combustion turbine or a generator. Those guys want to know how to remove the bearings. How do you do PMs? How do you adjust this valve? How do you set the clearances? And we’re getting a lot more requests for step-by-step 3D maintenance.

3D maintenance training?

Yes. With maintenance training, sometimes the trainer will say, “Okay, you guys are going to be rebuilding this valve. If you’ve never done it before, go through this training.” And they’ll watch an animated course that basically rotates the valve and shows them the flow paths and its components and how it works. And for dis-assembly, it’ll say “first hook a chain up to this hook, undo these bolts…” and so-on. And we’ll show every step for them.

The steps are right out of their standard operating procedures and there might be sixty steps. So, if they’re going out training on steps 45-50 that day, they can do an onboard meeting where the manager says, “Okay, let’s just review these five steps we’re going to do today. Here’s the safety equipment you need. Here’s your come-alongs…are there any questions? And you know, on step 48, we actually had a problem with this binding…” And he could show them some pictures of what they did to fix it. So you can use it for initial training or you can use it for a meeting that day before you go out and do the procedure.

In what format do they usually distribute that training?

We do a lot of it through our learning management system — that’s one way. We also create encrypted flash drives, and we can put them on DVDs and use them that way too.

Are training managers pretty accepting of online training?

Yes, they are. I know there’s some concern that using computer-based training means you’re going to be letting go of your trainers, but that’s not the case. I always suggest to trainers that they give students the computer-based course before they go to your class. That way, they’ve at least seen how a process or piece of equipment works and they understand the terms and you can start your class at a much higher level than if you have to start from the basics. Require them to get an eighty percent on the computer-based before class or maybe just make it available to them, and then in class, they can use the same content, but explain and answer questions. And that way, it’s the best of both worlds.

In the next five years, any major piece of equipment, people are going to require that they have a 3D animation explaining the equipment and 3D animation that shows step-by-step how to do maintenance. It’s going to be the norm in five years.

The instructors love that because they might have one guy in class with twenty years of experience sitting next to a guy who just got hired. And they’re in the same class. So you need to try and get people to a level where you can talk about more technical stuff rather than go over fundamentals for three days and bore the crap out of the guys who have done it for twenty years.

So I just say “it’s a training tool.” It’s a tool you can use. Sometimes guys like to know the terms and get their feet wet before they jump into a class. It’s not supposed to be the only piece of training you have, but it sure helps to break down barriers prior to class.

You mentioned growth in maintenance training. Where else do you growth over the next five to ten years?

Maintenance, safety, and site-orientation are three big areas of growth for us. In the near future, in the next five years, any major piece of equipment, people are going to require that they have a 3D animation explaining the equipment and 3D animation that shows step-by-step how to do maintenance. It’s going to be the norm in five years.

Thanks to Fred for the interview about 3D in manufacturing training. Please feel free to download our free Manufacturing Training Guide below before you leave!

Manufacturing Training from Scratch: A Guide

Create a more effective manufacturing training program by following these best practices with our free step-by-step guide.

I agree that this method of training greatly aids in the “visual” where it is difficult to provide a “hands on” application. I also view it as a great “safety” training before one even “steps out or into” the area of work to be performed. I currently attempt to “photograph” various steps of maintenance and training to provide the “visual” aspect and guide the individual to the proper sequencing and issues to “look for” before, during and after the work in performed.

Thanks for the feedback, Craig.