Consider this scenario, if you will.

You’re a training manager. Or maybe you’re someone else who is involved in training–the head of operations, or in HR, or the safety manager.

You or someone else at work determines there’s a performance problem. More specifically, you think your employees may have a skill gap.

What’s the answer? Create and lead some training? Well, maybe. But maybe not.

It’s easy to jump to the conclusion that training’s the answer for everything. But there’s nothing worse than creating a training program for a problem that the training can’t solve. You’ve now spent a bunch of money and time creating and delivering the training, and you’ve still got the problem to boot.

The best way to avoid this scenario is to take a step back and analyze the performance problem first. If you learn more about the problem, you can then figure out what the best solution for it is. Maybe it WILL be training, but maybe it will be something else.

- Learning Management Systems

- Online Workforce Training Courses

- Workforce Scheduling Software

- Mobile Training & Performance Apps

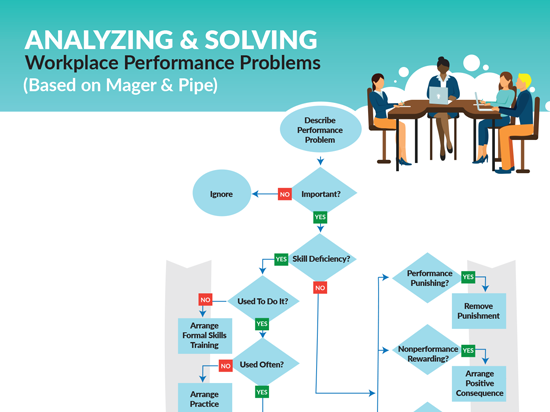

With that introduction down, let’s look at a process for analyzing performance problems and addressing skill gaps. This method was developed by the noted human performance improvement (HPI) expert Robert Mager and his collaborator Peter Pipe, and it’s explained in their classic book Analyzing Performance Problems, or, You Really Oughta Wanna.

Mager and Pipe’s method provides a series of steps for you to consider when you evaluate the proper solution to a performance problem at work. Once you’ve considered every item, you’ll be ready to propose the best solution–or a combination of solutions–and then put them into effect. This method will help you identify and close skill gaps as well as determine when a performance problem is NOT the result of a skill gap.

Here’s the method.

State and Describe the Problem with the Performance

First things first, right? State what the problem is and describe it so you know you fully understand it.

Ask Yourself: Does the Performance Problem Matter?

Once you’ve written the problem down, ask yourself if it’s really a big deal. Is it so significant that you should do something to fix it? Or is it really not a big deal, and should you move on to something else?

If you’ve decided it’s not a big deal, you stop here.

And if you’ve decided it IS a big deal, continue.

Is There A Skill Gap: Are Employees Not Performing Because They Don’t Have the Skill?

If you’ve decided that you want to fix this performance problem, you should ask yourself why employees aren’t already doing what you want them to do.

At this level, we can divide the answers to this question into two different categories. The first is that your employees don’t know how to do it or they can’t do it. The second category involves cases in which your employees can do it, but they’re not doing it for other reasons.

If your employees just don’t have the skill–meaning they can’t do what you want them to do–then go to the next section, titled “Yep, It’s a Skill Gap: When Your Employees Don’t Have the Necessary Skill(s).”

But if your employees DO have the necessary skills, go to the section after that, titled “No, It’s Not a Skill Gap: When Your Employees DO Have the Necessary Skill but Still Aren’t Performing.”

Yep, It’s a Skill Gap: When Your Employees Don’t Have the Necessary Skill(s)

If your performance problem exists because your workers don’t have the skills to do what you want them to do, you’ve got a few options to consider. Those are listed below in this section.

Is it Something They Used to Be Able to Do?

If the employees used to be able to do it, give them some guided practice with feedback telling them how they’re doing and what they’re doing right or wrong.

If the employees could never do it, consider a formal training session to teach them. Remember that training should include an explanation of what to do but also practice and feedback.

Is it Something They Do A Lot on the Job?

In some cases, your performance problem/skill deficiency will result from a case in which people perform the skill a lot on the job and, over time, they’ve begun to do it wrong. In that case, arrange feedback to get them back on track.

In other cases, it won’t be something they do a lot. In that case, set them up with some practice, and remember to include feedback.

Is There a Simpler Way?

When you’ve identified that you’ve got a performance problem and your workers currently have a skill gap, there may be times when you look for a simpler solution. Simpler, that is, than teaching your workers to perform the skill.

For example, maybe you can change the job so workers don’t have to perform the skill. An example of this would be buying a machine that performs the task.

Or, maybe you will continue to expect workers to perform the task, but you don’t think it’s necessary to have a formal training session to teach them. Maybe a little OJT, with an in-the-field demonstration and a bit of practice with feedback, is all they need.

Is the Employee Incapable of Performing the Task?

Finally, another thing to consider is that one or more employee may be simply incapable of performing the desired task. In that case, you may want to consider transferring the employee to a different position where he or she is better suited.

No, It’s Not a Skill Gap: When Your Employees DO Have the Necessary Skill but Still Aren’t Performing

In some cases, your employees CAN do what you want them to do, but they’re still not doing it. In those cases, there are a few things for you to consider to find out why they’re not doing it. Those are listed below.

Disincentive: The Employee is Somehow “Punished” for Performing the Desired Skill

Sometimes companies want employees to do something but don’t notice that there’s a disincentive to follow through and do them. For example, a safety manager may want employees to record all near-misses, but employees may not do this because they’re worried their coworkers will get upset. Or maybe you want employees to fill out a checklist every time they perform a procedure, but the checklists are stored on the opposite side of the plant.

If you’ve got a situation like this, training isn’t the solution. Instead, remove the disincentive that punishes the behavior you want, and you’ll see performance improve.

Incentive: The Employee is Somehow Rewarded for NOT Performing the Desired Skill

As you probably guessed, this is the flip-side of the “disincentive” coin we just discussed. Even though you want your employees to do something, they may have a built-in incentive to not do it. For example, maybe you want your service technicians to do something during each visit. But if not doing it (a) doesn’t cause an immediate problem and (b) gets them on to their next visit more quickly, in particular if you’ve set up a system that rewards them for completing as many service visits as possible, then you’ve set up a system that rewards them for not doing what you want them to do.

So, if you’ve got this issue at work, remove the reward for not performing the desired task.

No Consequences: It Doesn’t Matter to the Employees if They Do It Or Don’t Do It

Sometimes, employees can do something but there are no positive consequences to doing it and there are no negative consequences to not doing it.

For example, maybe you want your employees to fill out weekly reports. But if they don’t, someone else does it for them, and there’s no penalty to the employee who didn’t do them. On top of that, there’s no particular reward–even recognition in the form of saying “good job” or “thanks”–for doing the report.

If you’ve got a situation like this, then set up some consequences: good consequences for people who do what you want them to, and bad consequences for people who don’t.

Obstacles: Employees Don’t Do It Because Something Prevents Them From Doing It

The final “they have the skills to do it but still aren’t doing it” thing to consider is that there is some obstacle that prevents them from doing it.

This can be as simple as not having enough time. Maybe you want employees to wash their hands thoroughly every time they enter the production area, but their work requires them to leave and return to the area often and you also have set high expectations of how much they should do while they’re in the production area, meaning they just don’t have time to wash their hands that much.

Remove the obstacle (in this case, not enough time) and you’ll get better compliance.

(If you want to read a real-life example of this, Dr. Atul Gawande explains how doctors at a hospital have exactly this hand-washing problem and explains efforts to address that problem in his book Better.)

What’s the Best Solution?

Once you’ve worked your way through the questions above, you will have identified some potential solutions to your performance problem. Now it’s time to look at your possibilities and decide what the best solution would be.

Remember that in some cases, you’ll combine more than one solution.

Implement the Solution

And, with your best solutions now identified, it’s time to put them into effect at work. It’s not a bad idea to create some kind of form or checklist to help you make sure you get it done. Actually, that’s such a good idea we’re going to look into writing a post on that in the future.

Conclusion

That’s it. Hope you find this technique helpful.

Please leave a comment below if you have any questions or have any experience or tips on these issues.

Before you leave, download our free Analyzing & Solving Workplace Performance Problems flowchart, which we based on the flowchart created by Mager & Pipe in their Analyzing Performance Problems book.

Analyzing & Solving Workplace Performance Problems Flowchart

Download this free infographic, based on the famous Mager/Pipe flowchart from their book Analyzing Performance Problems, to determine the cause of workplace performance problems and then select the appropriate solution/intervention.

Differentiating between a skill gap and a performance gap is one of the first steps that need to be taken prior to planning an intervention. The type of intervention will be different once the type of gap has been identified. In order for any intervention to be effective, it is key that the proper type of solution is implemented.

Exactly, Darnell.