How would your company do during an OSHA fire extinguisher inspection? Or, more to the point, if an OSHA inspector were inspecting your workplace, would your fire extinguishers pass muster with the inspector?

We’re going to give you the information you need to pass that fire extinguisher inspection (Ha!!!–no pun intended on “PASS”).

And more importantly, the information you’ll need to know to make sure your fire extinguishers are ready to save property and lives in case of a fire. ‘Cuz that’s what they’re there for anyway, right?

- Learning Management Systems

- Online Safety and Health Training Courses

- Incident Management Software

- Mobile Safety Training Apps

OSHA Inspections–When They Happen, Why, and What Happens

If an OSHA inspector is auditing your work site, and if you have (or are supposed to have portable fire extinguishers, then those extinguishers will be something the OSHA inspector is going to want to check out.

But let’s back up, first. What happens during an OSHA inspection, and what triggers them? You will find this OSHA Inspections Fact Sheet helpful for that. Take a little time and read through that.

Have You Plans in Order

There’s a good chance an OSHA inspector will want to see some of your written safety plans at work.

For our purposes, we’ll discuss only the evacuation plan and fire prevention plan.

Evacuation Plan

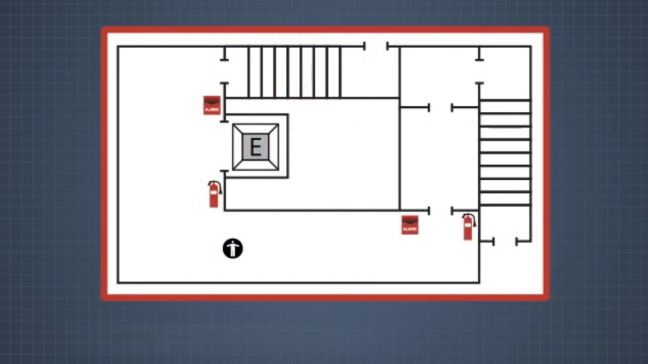

Your organization should have a written evacuation plan for dealing with disasters, including fires. This OSHA Evacatuion Plan eTool will help you create one.

OSHA noes that “for smaller organizations, the plan does not need to be written and may be communicated orally if there are 10 or fewer employees.” [29 CFR 1910.38(b)]

You may find this Emergency Action Plan Training video helpful for this.

Fire Prevention Plan

They may also want to see or know about your fire prevention plan, which is itself part of your evacuation plan. This OSHA resource will help you create a fire prevention plan.

Pay particular attention to this fire extinguisher resource page and this page of OSHA fire extinguisher requirements.

OSHA Fire Extinguisher Inspection Items

Make sure you (and your extinguishers) can pass the following inspection items. In many cases, you’ll have to document these.

General Requirements

An OSHA Inspector who’s inspecting your fire extinguisher may look for compliance with any of the following general requirements for fire extinguishers:

- Make sure you’re using only approved portable fire extinguishers. [29 CFR 1910.157(c)(2)]

- Mount, locate, and identify portable fire extinguishers so that they are readily accessible to employees without subjecting the employees to possible injury. [29 CFR 1910.157(c)(1)]

- Never use portable fire extinguishers that use carbon tetrachloride or chlorobromomethane extinguishing agents. [29 CFR 1910.157(c)(3)]

- Make sure portable fire extinguishers are maintained, fully charged, operating properly, and kept in designated places at all times except during use. [29 CFR 1910.157(c)(4)]

- Remove all soldered or riveted shell self-generating soda acid or self-generating foam or gas cartridge water type portable fire extinguishers that are operated by inverting the extinguisher to rupture the cartridge or to initiate an uncontrollable pressure generating chemical reaction to expel the agent. [29 CFR 1910.157(c)(5)]

Make sure your portable fire extinguishers are in compliance with all of the general requirements listed above.

Exemptions

OSHA does provide some exemptions. Here they are:

- Where the employer has established and implemented a written fire safety policy which requires the immediate and total evacuation of employees from the workplace upon the sounding of a fire alarm signal and which includes an emergency action plan and a fire prevention plan that meet the requirements of 29 CFR 1910.38 and 29 CFR 1910.39 respectively, and when extinguishers are not available in the workplace, the employer is exempt from all requirements of this section unless a specific standard in Part 1910 requires that a portable fire extinguisher be provided. [29 CFR 1910.157(b)(1)]

- Where the employer has an emergency action plan meeting the requirements of 29 CFR 1910.38, which designates certain employees to be the only employees authorized to use the available portable fire extinguishers, and which requires all other employees in the fire area to immediately evacuate the affected work area upon the sounding of the fire alarm, the employer is exempt from the distribution requirements in the selection and distribution section. [29 CFR 1910.157(b)(2)]

Selection and Distribution Requirements

OSHA also makes some fire extinguisher selection and distribution requirements. An employer must:

- Select and distribute the extinguishers based on the types of anticipated workplace fires and on the size and degree of hazard that would affect their use. [29 CFR 1910.157(d)(1)]

- Distribute portable extinguishers for use on Class A fires so that the travel distance for employees to any extinguisher is 75 feet (22.9 meters) or less. [29 CFR 1910.157(d)(2)]

- Use uniformly spaced standpipe systems or hose stations connected to a sprinkler system installed for emergency use by employees, instead of Class A portable fire extinguishers, provided that such systems meet the respective requirements of 29 CFR 1910.158 or 29 CFR 1910.159, that they provide total coverage of the area to be protected, and that employees are trained at least annually in their use. [29 CFR 1910.157(d)(3)]

- Distribute portable fire extinguishers for use on Class B fires so that the travel distance for employees to any extinguisher is 50 feet (15.2 meters) or less. [29 CFR 1910.157(d)(4)]

- Distribute portable fire extinguishers for use on Class C hazards on the appropriate pattern for the existing Class A or Class B hazards. [29 CFR 1910.157(d)(5)]

- Distribute portable fire extinguishers or other containers of Class D extinguishing agent for employee use so that the travel distance from the combustible metal working area to any extinguisher is 75 feet (22.9 meters) or less. Portable fire extinguishers for Class D hazards are required in areas where combustible metal powders, flakes, shavings, or similarly sized products are generated at least once every two weeks. [29 CFR 1910.157(d)(6)]

Inspection, Maintenance, and Testing Requirements

Here are the OSHA requirements for fire extinguisher inspection, maintenance, and testing requirements:

- Inspect, maintain, and test all portable fire extinguishers in the workplace. [29 CFR 1910.157(e)(1)]

- Visually inspect portable extinguishers or hoses monthly. [29 CFR 1910.157(e)(2)]

- Perform an annual maintenance check on portable fire extinguishers. Stored pressure extinguishers do not require an internal examination. Record the annual maintenance date and retain this record for one year after the last entry or the life of the shell, whichever is less. Make the record available to the Assistant Secretary upon request. [29 CFR 1910.157(e)(3)]

- Empty and maintain dry chemical extinguishers (that require a 12-year hydrostatic test) every six years. Dry chemical extinguishers that have non-refillable disposable containers are exempt from this requirement. When recharging or hydrostatic testing is performed, the six-year requirement begins from that date. [29 CFR 1910.157(e)(4)]

- Provide alternate equivalent protection when portable fire extinguishers are removed from service for maintenance and recharging. [29 CFR 1910.157(e)(5)]

Hydrostatic Testing Requirements

There are quite a few requirements regarding hydrostatic testing of fire extinguishers that an OSHA inspector may look into. Be sure you’ve done all this and can prove it:

- Assure that hydrostatic testing is performed by trained persons with suitable testing equipment and facilities. [29 CFR 1910.157(f)(1)]

- Assure that portable extinguishers are hydrostatically tested at the intervals listed in Table L-1 of this section, except under any of the following conditions [29 CFR 1910.157(f)(2)]:

- When the unit has been repaired by soldering, welding, brazing, or use of patching compounds. [29 CFR 1910.157(f)(2)(i)]

- When the cylinder or shell threads are damaged. [29 CFR 1910.157(f)(2)(ii)]

- When there is corrosion that has caused pitting, including corrosion under removable name plate assemblies. [29 CFR 1910.157(f)(2)(iii)]

- When the extinguisher has been burned in a fire. [29 CFR 1910.157(f)(2)(iv)]

- When a calcium chloride extinguishing agent has been used in a stainless steel shell. [29 CFR 1910.157(f)(2)(v)]

- Assure that an internal examination of cylinders and shells to be tested is made before the hydrostatic tests in addition to an external visual examination. [29 CFR 1910.157(f)(3)]

Training and Education Requirements

An OSHA inspector may also want to know if you’ve educated and trained your employees to use the portable fire extinguishers properly. Here are the employee training requirements for portable fire extinguishers an OSHA inspector may want to investigate:

- Provide an educational program to familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage fire fighting. [29 CFR 1910.157(g)(1)] Provide this education when employees are first hired and once a year thereafter. [29 CFR 1910.157(g)(2)]

- Train employees (who have been designated to use fire fighting equipment in the emergency action plan) in the use of the equipment. [29 CFR 1910.157(g)(3)] Provide this training when employees are first given this assignment and once a year thereafter. [29 CFR 1910.157(g)(4)]

OSHA Small Business Compliance Guide Checklist

The OSHA Small Business Compliance Guide offers this checklist for you to use:

- Is your local fire department familiar with your facility, its location and specific hazards?

- If you have a fire alarm system, is it certified as required and tested annually?

- If you have interior standpipes and valves, are they inspected regularly?

- If you have outside private fire hydrants, are they flushed at least once a year and on a routine preventive maintenance schedule?

- Are fire doors and shutters in good operating condition?

- Are fire doors and shutters unobstructed and protected against obstructions, including their counterweights?

- Are fire door and shutter fusible links in place?

- Are automatic sprinkler system water control valves, air and water pressure checked periodically as required?

- Is the maintenance of automatic sprinkler systems assigned to responsible persons or to a sprinkler contractor?

- Are sprinkler heads protected by metal guards if exposed to potential physical damage?

- Is proper clearance maintained below sprinkler heads?

- Are portable fire extinguishers provided in adequate number and type and mounted in readily accessible locations?

- Are fire extinguisher recharged regularly with this noted on the inspection tag?

- Are employees periodically instructed in the use of fire extinguishers and fire protection procedures?

Additional Articles about OSHA Fire Extinguisher Requirements and Using a Fire Extinguisher

In addition to this article, you may find the following articles related to fire safety and fire extinguishers helpful:

- OSHA Fire Extinguisher Safety Training Requirements

- How to Use a Fire Extinguisher – Step by Step Guide

- Types of Fire Extinguishers – Which One To Buy

- OSHA Fire Extinguisher Mounting Height, Placement & Signage Requirements

Finally, you may want to consider our online fire extinguisher safety training video. Here’s a short sample:

OSHA Fire Extinguisher Inspection Requirements

Hope this article helps. Remember that it’s great to pass an OSHA fire extinguisher inspection so you and your company don’t get in trouble with OSHA, but the real purpose is to protect and save lives.

Before you go, feel free to DOWNLOAD OUR FREE ONLINE SAFETY TRAINING BUYER’S GUIDE CHECKLIST, BELOW.

Online Safety Training Buyer’s Guide Checklist

Learn how to evaluate the different online safety training solutions that exist to find one that best fits your company’s needs with our FREE informative guide and checklist.