Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a manufacturing performance metric that is used to identify the sources of lost production and measure improvement efforts. In this course we will discuss the purpose of OEE and how it is calculated. We will define availability, performance, and quality factors. We will also describe how to implement and analyze OEE and define the Six Big Losses, as well as how to reduce them.

Request a demoCourse Details

Learning Objectives

- Define Overall Equipment Effectiveness, or OEE

- State the purpose of OEE

- Define availability, performance, and quality factors

- Describe how OEE is calculated

- List the required data and describe how to implement OEE

- Describe how to analyze OEE

- Define each of the Six Big Losses

- Describe the OEE improvement methodologies that can be applied to reduce each of the Six Big Losses

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video, MobileReady |

| Based on: | Industry Standards and Best Practices |

Key Questions

What kind of processess can OEE be applied to?

OEE can be applied to almost any manufacturing process. It doesn’t matter if there is only one machine or a long production line made up of several machines.

What is considered “unscheduled time” in OEE?

When forces outside the company’s control cause production to stop it is considered unscheduled time. This can include power outages, weather, or worker strikes.

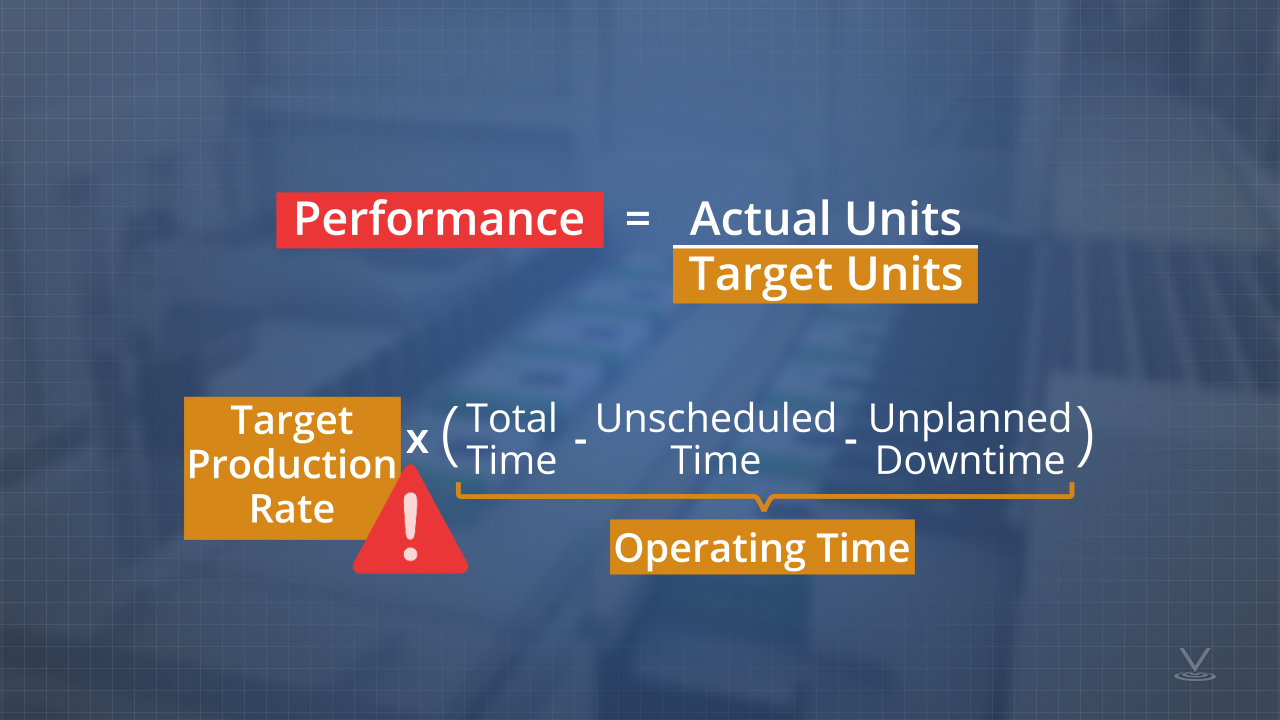

What is the best way to calculate the performance factor of a process?

The best way to calculate the performance factor is always to use the maximum theoretical production rate. This is sometimes referred to as the nameplate capacity or design speed for the equipment.

What are the Six Big Losses?

The six big losses are breakdowns, changeovers, minor stops, reduced speed, startup defects, and waste.

What is a method to reduce changeover time in a process?

The single-minute exchange of dies, or SMED methodology is one way to approach reducing changeover time. This method breaks down changeover improvement into three necessary steps, which are: 1. Identifying and separating the changeover tasks into internal and external tasks. 2. Evaluating and converting internal tasks to external tasks, and 3. simplifying the remaining internal tasks.

Sample Video Transcript

OEE can be applied to almost any manufacturing process. It doesn’t matter if there is only one machine or a long production line made up of several machines. The application of OEE will vary slightly, but the principles are the same. For purposes of this module, a tissue converting line that makes toilet paper will be used for example purposes because OEE concepts can be easily applied and illustrated. Large rolls of tissue from a tissue machine are unwound and rewound in smaller rolls called logs. These logs are then cut to consumer-length rolls and wrapped in various package configurations. The packages are then placed in a bundle or case and shipped to customers. The important concept is that we are starting with raw materials that are transformed by one or more manufacturing steps into a usable product.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.