Operator Basic Care

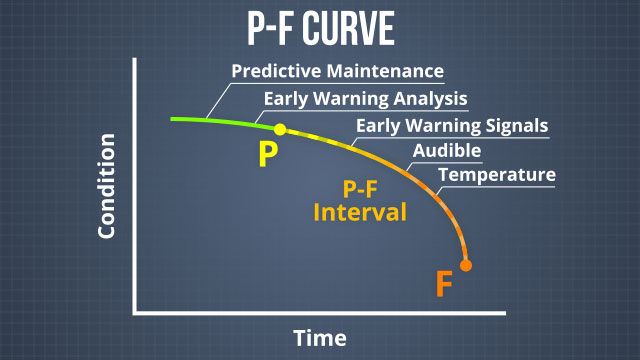

Operator basic care (also known as operator essential care, operator driven reliability, asset basic care, or autonomous maintenance) is an equipment reliability program. Although the name and program details can vary, the general concept is to involve operators in the maintenance of their equipment. By engaging all employees, a consistent product output and quality can be maintained throughout the expected lifespan of a machine. The theory is that maintenance should be driven by operators because they spend the most time with the equipment, so they know the most about the current machine condition. Operator basic care provides a foundation for a successful predictive maintenance program. This course covers the basic concepts and best practices of Operator Basic Care programs.

Request a demoCourse Details

Learning Objectives

• Describe the purpose and benefits of an Operator Basic Care program

• List typical basic care tasks or activities

• Describe the importance of housekeeping

• Describe the importance of lubrication

• Describe the role of inspections in Operator Basic Care programs

• Identify and describe typical inspection tools

• Identify and describe typical operator adjustments and minor repairs

• Describe the importance of basic care documentation and reporting

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese, French, Polish |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is Operator Basic Care?

Operator Basic Care is an equipment reliability program that involves operators in the maintenance of their equipment.

What is the purpose of Operator Basic Care?

The goal of Operator Basic Care is to keep machines running as well as they did when they were new. Benefits include: Increased reliability, communication, knowledge, quality, safety, along with decreased operating and maintenance costs.

What are typical operator activities in a Basic Care program?

Operator responsibilities typically include housekeeping, lubrication, performing minor maintenance tasks, inspecting equipment for defects and documenting inspection results.

What are the 5 Rights of Lubrication?

A good lubrication program should ensure the Right type and quality of lubricant is applied in the Right amount, in the Right place, and at the Right time.

What are minor maintenance tasks that operators may be expected to perform?

Some examples of minor maintenance tasks are replacing normal wear items, unplugging drain lines, replacing some broken parts, adjusting seal water flows, performing changeovers, replacing filters, and tightening loose bolts.

Sample Video Transcript

Common inspection items include operating hours of the machine, fluid levels such as oil or fuel, process variables such as temperatures, pressures, or flows, equipment conditions such as bearing temperatures, fasteners, guarding, etc., vibration readings, and ultrasonic levels. Operator basic care inspections should be measurable and repeatable, not subjective. No matter who does the inspection, the results should be the same. A good inspection includes detailed task instructions such as, “Ensure the gearbox oil level is in the middle third of the sight glass tube,” versus, “Check gearbox.” Including pictures of the gauge on the inspection form and visual controls on the gauge itself, will ensure the inspection is objective.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.