Safety Management: Industrial Hygiene Basics

“Industrial hygiene” (or “occupational hygiene,” outside of the U.S.) is the discipline of evaluating and controlling workplace hazards in order to protect the health and well being of workers and the community. This involves monitoring of work environments, evaluating exposures to hazards, and employing controls to prevent or minimize exposures and their effects. This course describes the job responsibilities of an industrial hygienist, discusses common workplace hazards, and details measures that can be used to control these hazards.

Request a demoCourse Details

Learning Objectives

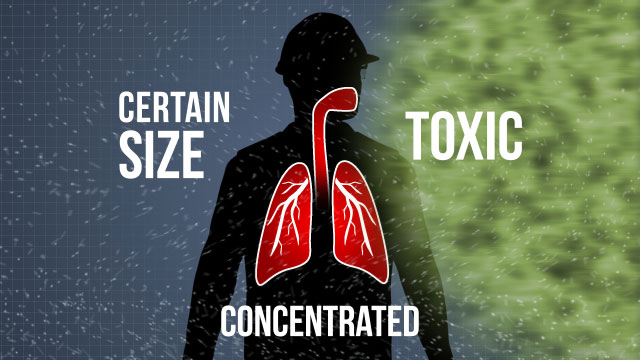

Define the terms “industrial hygiene” and “ergonomics” Describe the responsibilities of an industrial hygienist List and describe common workplace hazards, including airborne contaminants, chemical hazards, biological hazards, and physical hazards, including noise hazards and ergonomic hazards Describe the different types of airborne contaminants Identify the components of a “worksite analysis,” including a comprehensive survey, change analysis, job hazard analysis, and regular inspections Identify and describe the components of the “Hierarchy of Controls”

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | 29 CFR §§ 1910.94-98: Occupational Health and Environmental Control 29 CFR §§ 1910.101-126: Hazardous Materials 29 CFR §§ 1910.132-138: Personal Protective Equipment 29 CFR §§ 1910.211-219: Machinery and Machine Guarding 29 CFR §§ 1910.241-244: Hand and Portable Powered Tools and Other Hand-Held Equipment 30 CFR §§ 57: Air Quality, Radiation, Physical Agents, and Diesel Particulate Matter |

Key Questions

What kind of education and training does a certified industrial hygienist have?

Certified industrial hygienists typically have a degree in (or have studied extensively) chemistry, biology, math, engineering, or other science-related topic. They have also completed additional IH coursework, have several years of work experience, and have passed a certification examination.

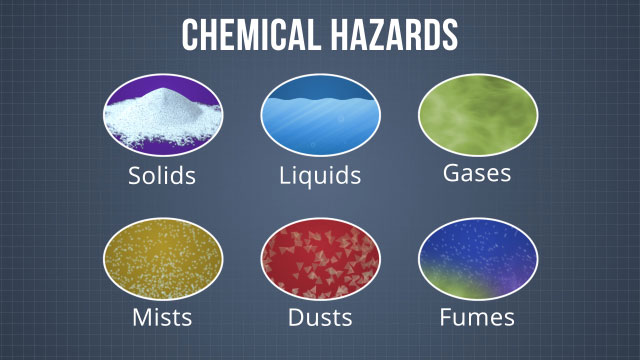

What are the most common workplace hazards?

Airborne contaminants, chemical hazards, biological hazards, and physical hazards, including noise hazards and ergonomic hazards.

What is the main difference between chemical hazards and biological hazards?

Biological hazards, like bacteria and viruses, have the ability to replicate themselves; chemical hazards do not.

What kinds of precautions should be used to protect workers from chemical hazards?

Workers who must work with or around chemicals should review all relevant safety data sheets, understand the potential hazards and proper precautions, use all required personal protective equipment (PPE), and follow all established procedures and protocols.

What is the “Hierarchy of Controls”?

An arrangement of hazard controls, with the most effective at the top and least effective at the bottom. From top to bottom, they include hazard elimination, engineering controls, administrative controls, and personal protective equipment (PPE).

Sample Video Transcript

Sound is inevitable in workplaces, but some sounds or noises can be bothersome and even harmful. Excessive noise at the workplace deserves extra attention because “noise-induced hearing loss” is one of the most prevalent health concerns for workers today. Sound is produced by vibrating objects or bodies. When we speak, air flowing from our lungs causes our vocal chords to vibrate. The sound of our voice then travels through the air as pressure waves, which travel to the inner ear and are interpreted by the brain. The frequency and intensity of the pressure waves determine the pitch and volume of the sound.

Additional Resources

- Occupational Safety and Health Administration (OSHA) – www.osha.gov

- OSHA Publications – https://www.osha.gov/Publications/OSHA3143/OSHA3143.htm

- American Industrial Hygiene Association (AIHA) – www.aiha.org

- AIHA Topics – https://www.aiha.org/publications-and-resources/TopicsofInterest/Pages/default.aspx

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.