Hot Water Boilers

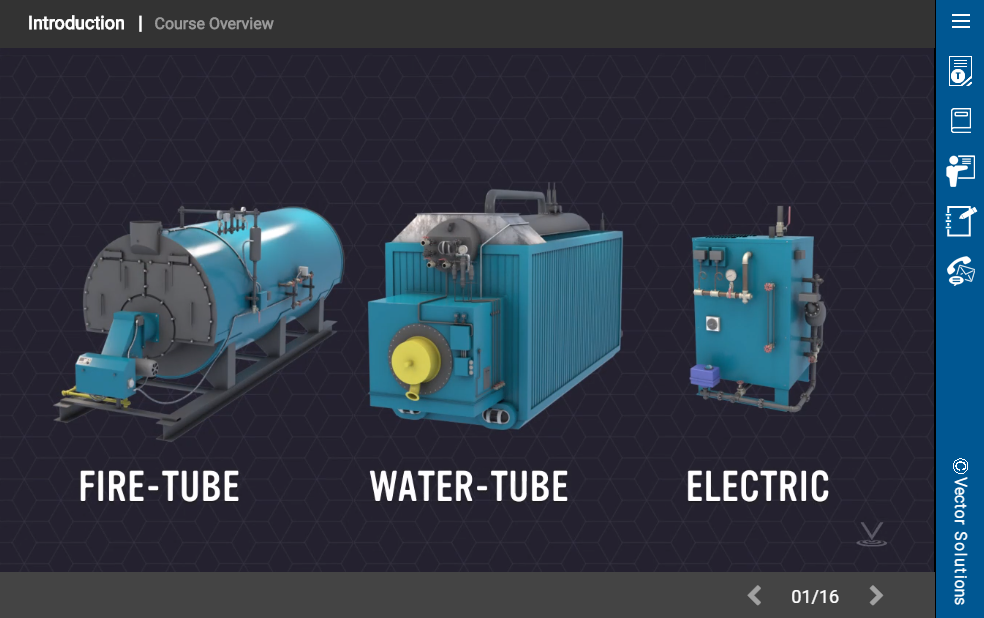

Boilers are fuel-burning appliances that produce either hot water or steam that gets circulated through piping for heating or process uses. The boiler operator is responsible for the safe and efficient operation of the boiler system and with proper maintenance, a hot water boiler will provide reliable heat and hot water to facilities for many years. This interactive online course explains how a boiler works and the different types of boilers. It describes the responsibilities of a hot water boiler operator and the short- and long-term inspections and maintenance for boiler systems.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

- Explain how a boiler system works

- Identify the different types of boiler systems

- Locate the main components of a typical boiler system

- Describe the responsibilities of a hot water boiler operator

- List the short- and long-term inspections and maintenance for boiler systems