Broke Cleaning and Screening

“Broke” refers to partly or fully manufactured paper or board that is discarded from paper or board making, converting, and finishing processes. It also refers to the stock made by repulping these materials. Broke is continuously being produced and it is the job of the “broke system” to collect this valuable resource and supply it back to the paper or board making process for reuse. Many broke systems include cleaning and screening stages just before the broke fiber is returned to the machine furnish. The purpose of broke cleaning and screening systems is to remove contaminants from the broke stream, break apart fiber flakes and bundles in the broke to improve sheet uniformity and minimize fiber losses, and return a clean, consistent flow of broke to the machine furnish.

Request a demoCourse Details

Learning Objectives

• List the functions of broke cleaning and screening systems • List safety hazards and safety guidelines related to broke systems • Explain the purpose of high density cleaners, broke deflakers, and broke screens in broke systems • Describe process flows in a typical broke cleaning and screening system • Describe the operation of a high density cleaner junk trap • Explain how a two-stage screening system works • Explain why consistency control is important in broke cleaning and screening systems • Describe why it is important for broke to be metered consistently into the machine furnish

Specs

| Course Level | Intermediate |

| Languages | English, French, Russian |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

Why would you need both cleaners and screens? Don’t they both remove contaminants from broke?

Broke systems often use both high density cleaners and pressure screens. HD cleaners remove heavy contaminants, while screens remove large contaminants and help break up fiber flakes.

What are the process flows for a typical broke system?

Typically, broke is pumped from a broke storage chest to a high density cleaner, through a deflaker, and on to a broke screening system, before it is blended back in to the machine furnish.

Why is it important to control broke consistency?

Consistency swings can negatively affect the machine-direction weight profile. Also, if the consistency is too high, this can cause pressure screens to mat over and plug.

How does broke fiber differ from virgin fiber?

Broke fiber has already been screened, cleaned, refined, and perhaps chemically treated or dried. Therefore, it does not hold water as well or respond as well to refining.

Where is broke typically added back to the paper or board making process?

Broke is typically reintroduced to the process at the blend chest or machine chest in the thick stock system.

Sample Video Transcript

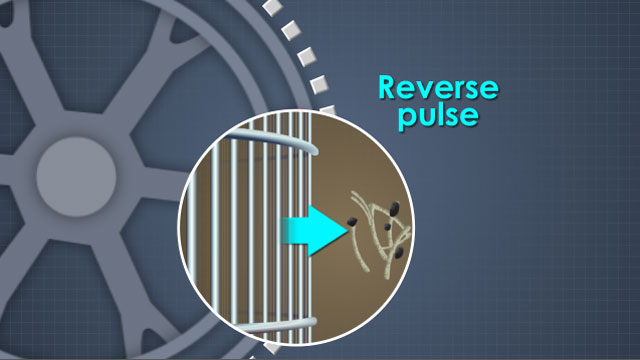

The purpose of a broke deflaker is to break apart any fiber bundles or flakes that remain in the broke-stuck after repulping in order to improve sheet uniformity. This can improve several sheet properties. A deflaker is similar to a disk refiner in both appearance and operation. The broke enters at the top is fed into the centre of two disks, flows outward between a stationary disk and a high-speed rotor disk and then flows out an outlet at the top. The difference between a deflaker and refiner is that a deflaker has little effect on stock freeness and fiber morphology. Deflakers are designed to break apart fibre bundles not refine the fibres.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.