January 19, 2024 15 min read

The 6 Steps of Lockout/Tagout (LOTO) Safety Procedures

Industry:

Solution:

What is LOTO?

LOTO stands for lockout/tagout. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm.

In this article, we’ll look at the basics of lockout/tagout and LOTO safety, including some basic definitions, relevant OSHA regulations and informational resources, and steps to follow when performing lockout tagout procedures.

The Purpose of Lockout/Tagout and LOTO Safety

When machines or equipment are being prepared for service or maintenance, they often contain some form of “hazardous energy” that can cause harm to people in the area.

When we talk about hazardous energy, we mean any type of energy that can be released and might harm a person. This could include energy of the following types:

- Chemical

- Electrical

- Hydraulic

- Mechanical

- Pneumatic

- Thermal

- Other sources of energy

Without the use of proper LOTO safety procedures, the serviced equipment can unexpectedly start up or otherwise release these forms of energy. This can lead to serious (even potentially fatal) injuries to the people working on the machine and to others working in the area or living in the community.

Consider just a few examples:

- A worker is servicing a press, another worker comes by and starts the press, and the service worker is caught up in the press, causing an amputation

- Workers are repairing a connection in piping, and somewhere up that same line another worker opens a valve, sending fluids down the pipe that ultimately spill on and burn the maintenance workers

- A conveyor jams, a worker reaches in to try to clear the jam, the conveyor jam is suddenly and unexpectedly freed, and the worker is crushed as a result

- A worker is servicing a machine, and at the same time internal wiring in the machine shorts, causing the maintenance worker to receive an electrical shock

- All of these are examples of hazardous energy causing harm. And that’s what LOTO safety is all about–making sure these types of hazardous energy are controlled so they’re never released and can’t cause harm.

Lockout Tagout Safety Training Courses

Learn More

Lockout/Tagout is Part of an Energy Control Program

Every workplace should have an energy control program in place, with LOTO safety being one part of that program. An energy control program includes established procedures for using locks and tags; the locks and tags themselves; lockout/tagout procedures, policies, and equipment; and periodic reviews and inspections of the system (at least annually).

OSHA’s Lockout/Tagout standard also requires employers to train each worker to ensure that they know, understand, and are able to follow the applicable provisions of the hazardous energy control procedures. Workers must be trained in the purpose and function of the energy control program and have the knowledge and skills required for the safe application, usage, and removal of energy control devices.

This standard requires that employees who work in an area where energy control procedure(s) are utilized be instructed in the purpose and use of the energy control procedure(s), and especially trained not to attempt to restart or reenergize machines or other equipment that are locked or tagged out.

All employees who employers authorize to lockout machines or equipment and perform any service or maintenance operations must be trained each year to recognize sources of hazardous energy in the workplace, the type and magnitude of energy found in the workplace, and the means of isolating and/or controlling the energy.

If new energy control methods are introduced, or existing controls are changed, OSHA requires employees to be re-trained on how to use any new or updated methods.

Six Steps of LOTO Safety & Lockout/Tagout Procedures

A lockout/tagout procedure should include the following six steps:

- Preparation

- Shutdown

- Isolation

- Lockout/tagout

- Stored energy check

- Isolation verification

Let’s look at each of these steps of LOTO safety more closely in the sections below.

Lockout/Tagout Step 1: Preparation

The first step of locking and tagging out equipment for service and maintenance is to prepare. During the preparation phase, the authorized employee must investigate and gain a complete understanding of all types of hazardous energy that might be controlled. In addition, it’s important to identify the specific hazards and of course means for controlling that energy.

Lockout/Tagout Step 2: Shut Down

With planning complete, the actual process of powering down and locking out machines begins.

At this point, it’s time to shut down the machine or equipment that will be serviced or maintained. Another important part of this step is to inform any employee affected by the shutdown, even if they won’t play a role in the service or maintenance. An example of affected employees include machine operators who need to know that their machine should not be operated, or any other employees, visitors, or contractors who would be working in the area.

Lockout/Tagout Step 3: Isolation

The next step of the lockout/tagout procedure is to isolate the machine or equipment from any source of energy.

This may mean any number of things, such as turning off power at a breaker or shutting a valve.

Lockout/Tagout Step 4: Lockout/Tagout

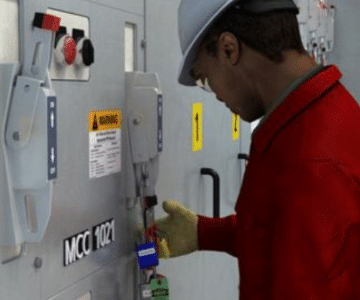

With the machine or equipment isolated from its energy source the next step of lockout/tagout is to actually lock and tag out the machine. It’s fair to say that this entire six-step process takes its name from this step.

During this step, the authorized employee will attach lockout and/or tagout devices to each energy-isolating device. The point is to apply the lockout device on the energy-isolating device in a way so it says in the “safe” position and cannot be moved to the unsafe position except by the person performing the lockout.

Tagout refers to applying a tag on the device as well. This tag includes the name of the person who performed the lockout and additional information.

Lockout/Tagout Step 5: Stored Energy Check

Even after the energy source has been disconnected, in step 3 of the lockout safety process, and the machine has been locked out, in step 4, that doesn’t entirely guarantee that there’s no hazardous energy still stored within the machine or that it’s safe to perform maintenance.

At this time, it’s important to look for any hazardous energy that’s been “stored” within the machine, or any “residual” energy. During this phase, any potentially hazardous stored or residual energy must be relieved, disconnected, restrained, or made non-hazardous in some other way.

Lockout/Tagout Step 6: Isolation Verification

This last step is all about making sure.

Yes, you’ve shut down the machines, isolated them from their source of power, locked them out, and checked for hazardous stored energy. But now’s the time to double-check that you did it all right and it’s now safe to work on the machine or equipment.

At this point, an authorized employee verifies the machine has been properly isolated and de-energized.

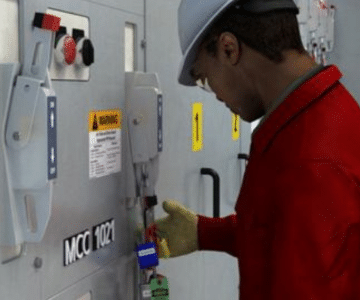

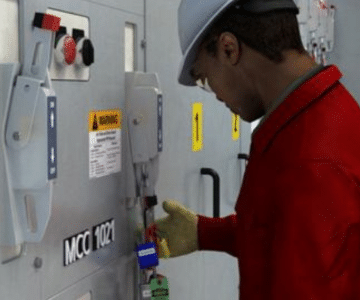

The example images shown above are all from one of our two online Lockout-Tagout training courses. We have one for Affected Employees and a second for Authorized Employees.

Conclusion: LOTO Safety in 6 Easy Steps

We hope you enjoyed learning the six basic steps of every lockout/tagout procedure. If your workplace needs help with developing lockout tagout training, at Vector Solutions we offer several lockout training courses within our extensive online safety training library that can be leveraged to better protect your team from unintentional exposures to all types of hidden energy and electrical hazards.

Our online lockout tagout training has helped thousands of organizations to comply with OSHA’s standard for the Control of Hazardous Energy and protect their employees from harm. Contact us today to learn more about how we can support your workplace’s environmental health and safety training.

Facilities Maintenance Kick-Start Smart Guide

Download