March 18, 2024 8 min read

Construction Hazards: Common Risks & How to Avoid Them

Industry:

Solution:

Hazards in construction pose a significant threat to workers. Understanding them is not just a regulatory requirement, but a crucial step towards ensuring the safety of your workforce. In this blog, we break down a list of 17 construction hazards and offer practical solutions for a safer construction industry.

Understanding Construction Hazards

Construction hazards encompass a broad range of potential threats to the well-being of workers and the overall safety of construction sites. These hazards arise from various sources, including operating heavy machinery, exposure to different materials, and environmental conditions.

Proactively identifying these risks is fundamental to creating a safe working environment. Let’s explore a detailed list of construction hazards, each presenting unique challenges that demand proactive preventive measures and strict safety protocols.

Construction Hazards List

- Falls. Elevated workspaces, unguarded edges, and inadequate fall protection lead to more falls.

- Struck-By Hazards. Workers face the danger of being struck by moving vehicles, equipment, or falling objects.

- Caught-In/Between Incidents. The risk of limbs getting caught in machinery or workers being compressed between objects.

- Electrical Hazards. Exposed wiring, faulty equipment, and unsafe electrical practices heighten the risk of electric shocks.

- Collapse of Trenches and Excavations. Poorly supported trenches or excavations can collapse, leading to burial injuries.

- Chemical Exposure. Handling and exposure to hazardous chemicals demand strict adherence to safety protocols, including proper storage, usage, and PPE.

- Heavy Equipment. Mishaps involving cranes, forklifts, and other heavy machinery require rigorous operator training, maintenance, and communication.

- Fire and Explosions. Construction sites require fire prevention measures and emergency response planning.

- Noise. Prolonged exposure to loud construction noises can result in hearing loss.

- Vibration. Tools and equipment that cause vibrations can lead to long-term health issues.

- Heat Stress. Working in hot environments raises the risk of heat-related illnesses. Adequate hydration, breaks, and shaded areas are crucial to avoid heat stress.

- Biological Hazards. Exposure to mold, bacteria, and other biological agents requires proper sanitation, personal hygiene, and protective measures.

- Ergonomic Strain. Improper lifting techniques and poor ergonomics contribute to musculoskeletal disorders.

- Slips and Trips. Uneven surfaces, debris, and inadequate housekeeping lead to slips and trips.

- Respiratory Hazards. Dust, fumes, and airborne contaminants pose respiratory risks.

- Confined Spaces. Working in confined spaces requires training, ventilation, and emergency rescue plans to prevent asphyxiation or entrapment.

- Mental Health. Lack of mental health support contributes to accidents. With the construction industry having one of the highest suicide rates in the U.S., mental health is becoming one of the biggest risks to workers.

4 Most Common Hazards in Construction

In the construction industry, certain hazards occur more often than others and contribute to more accidents and fatalities. These construction work hazards are commonly called the “Focus Four” by the Occupational Safety and Health Administration (OSHA).

Identifying and addressing these hazards are crucial for enhancing construction site safety and preventing life-threatening incidents.

- Falls. The greatest risk on a construction site is falling. Implementing stringent fall prevention measures, such as guardrails, safety nets, and personal fall arrest systems, is essential to mitigate this risk.

- Struck-By. Struck-by incidents can occur if workers are in the path of vehicles, equipment, and falling objects. Vigilant supervision, warning systems, and personal protective equipment play key roles in preventing such accidents.

- Caught-In/Between. Workers may face the risk of limbs getting caught in machinery or being compressed between objects. Proper machine guarding, employee training, and adherence to safety procedures are critical to preventing caught-in/between accidents.

- Electrocution. Exposure to live wires, unsafe electrical practices, and faulty equipment increase the risk of electrical shocks and burns. Ensuring proper electrical installations, using insulated tools, and providing comprehensive electrical safety training are vital components of minimizing electrical hazards.

OSHA Reporting & Recordkeeping Guide

This guide prepares EHS Professionals with a comprehensive understanding of OSHA’s rules and requirements for recording an injury or illness

View Guide

How to Avoid Hazards in the Construction Industry

Ensuring a safe construction site requires a proactive approach to identify, assess, and mitigate potential hazards. Let’s explore three strategies for avoiding hazards in the construction industry.

Proper EHS Management

Effective EHS management is the cornerstone of a safe construction environment. This involves systematically identifying hazards, conducting risk assessments, and implementing controls to minimize or eliminate risks. Regular site inspections, hazard communication, and comprehensive safety protocols contribute to a culture of safety where everyone is collectively responsible for identifying and addressing potential hazards.

Therefore, implementing the right Environmental, Health, and Safety (EHS) management software is key to managing, documenting, reporting on, and correcting safety hazards on the construction site.

Learn more about our best-in-class EHS management solution ⬇️

Vector EHS Management

Manage your entire environmental health and safety program in our configurable system to save time and improve efficiency in your safety department

Learn More

OSHA 10 Construction Training

OSHA requires that all construction personnel complete OSHA 10 Construction training in order to equip them with essential industry and safety knowledge.

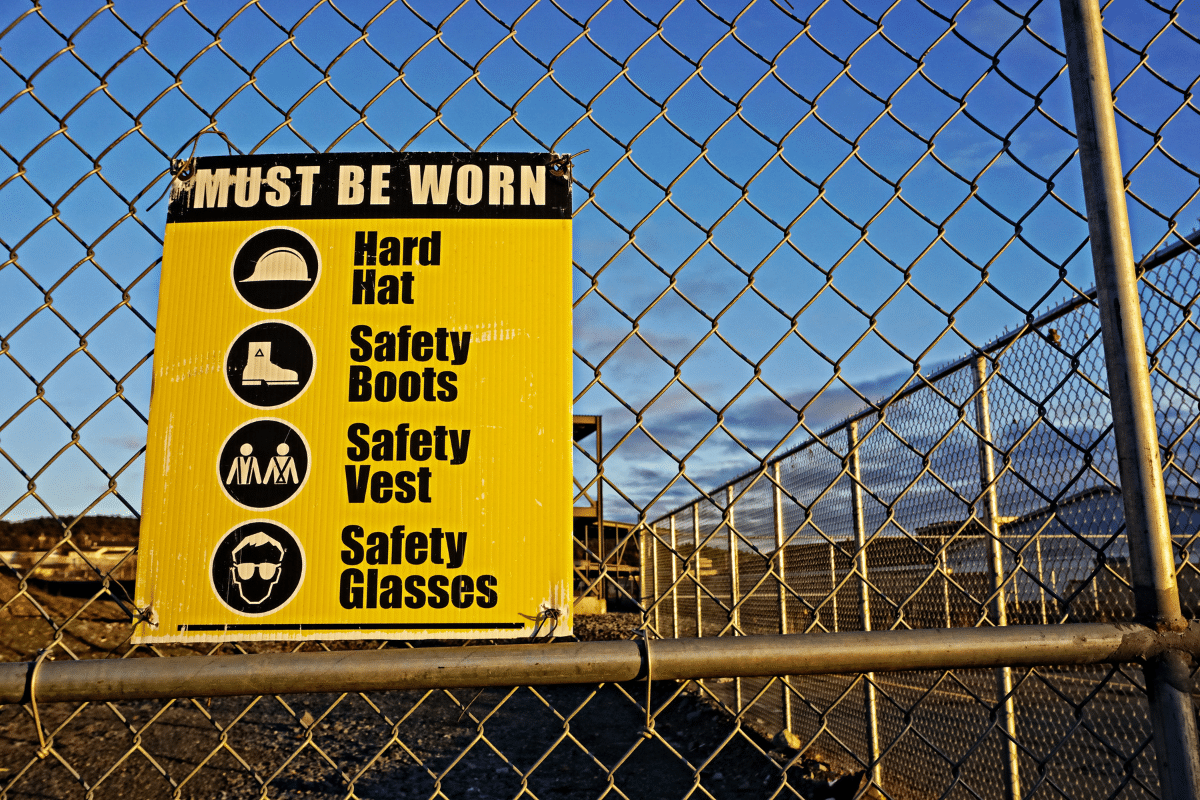

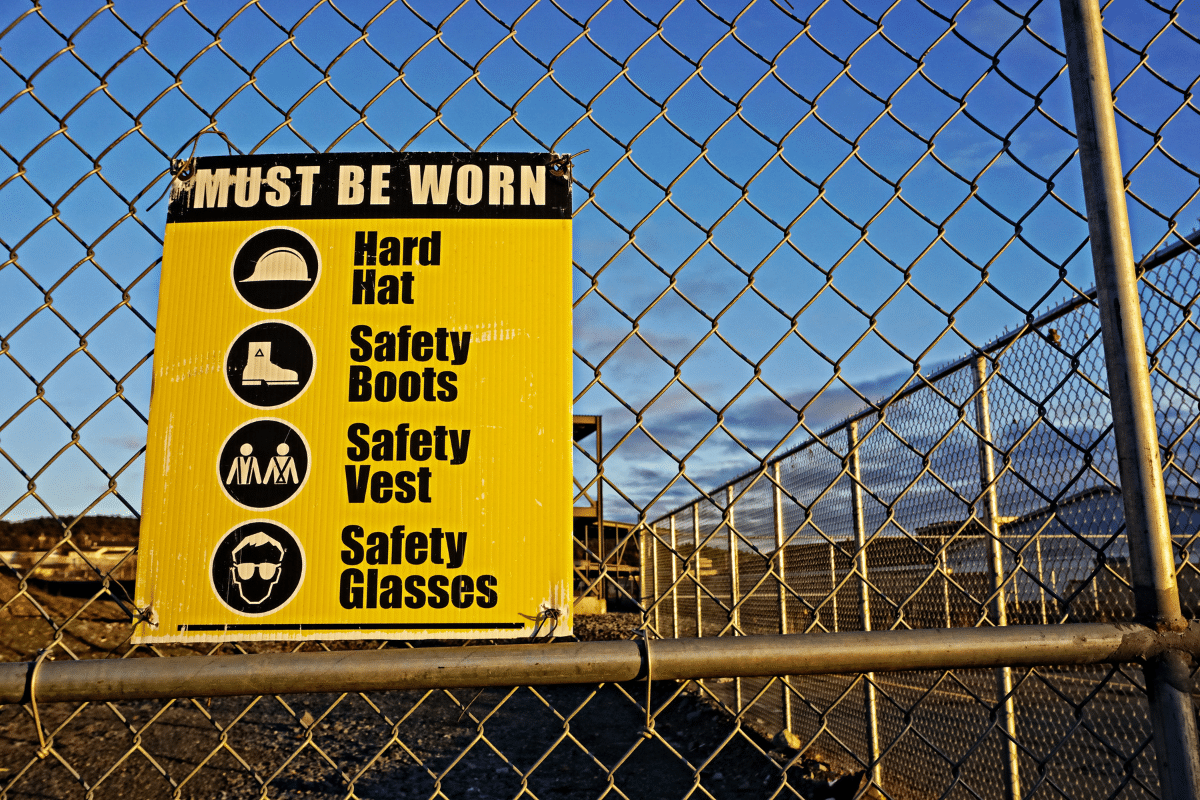

The OSHA 10 (or OSHA 30) training program provides a comprehensive overview of industry-specific hazards and safety practices. It covers topics such as fall protection, electrical safety, and personal protective equipment (PPE), empowering workers to recognize and avoid potential risks on the job.

Learn more about Vector Solutions’ construction training options:

HSE Training

In addition to construction-specific training, providing robust Health, Safety, and Environmental (HSE) training can provide a more holistic approach to employee well-being.

HSE training should cover a range of topics, including emergency response, hazard communication, and employee well-being. By integrating HSE principles into daily operations, construction firms can foster a culture of safety that prioritizes the physical and mental health of their workforce.

Why Construction Hazard Prevention is so Important

Preventing hazards in construction is not merely a regulatory requirement; it is a fundamental imperative that directly impacts the well-being of workers, the financial health of construction firms, and the overall success of projects. The benefits extend far beyond immediate safety concerns, creating a positive ripple effect on retention, worker engagement, and long-term business success.

1. Safety and employee well-being.

The most important reason to focus on addressing hazards in the construction industry is that it saves lives and prevents serious injury.

In 2021, there were nearly 170,000 total injuries recorded in construction. And in 2022, 1069 construction workers died on the job, making construction have the third highest fatality rate in the United States. Proper training and safety measures could have prevented these deaths and injuries.

2. Cost Savings

Even though keeping people safe from harm is reason enough to invest in construction safety, there is a huge financial upside to preventing injuries and deaths.

- Full-time construction workers missed 24.2 million hours of work due to injury or illness in 2022.

- The average OSHA penalties from 2011 – 2020 were $102.7 million, at a cost of nearly $3,000 per inspection and $1,460 per citation.

- It’s estimated that the annual cost of construction-related deaths is $5 billion.

- Worker’s compensation claims from the top five construction injuries is $7.87 billion.

Proactive hazard prevention translates directly into financial savings for construction firms. Avoiding accidents means minimizing medical expenses, workers’ compensation claims, and potential legal liabilities. Moreover, it prevents project delays and disruptions, ensuring timely and cost-effective project completion.

3. Increased Productivity

A safe and hazard-free workplace fosters higher levels of productivity. With the help of AI tools for construction, you can improve safety and worker productivity significantly.

Workers can focus on their tasks without fear of potential dangers, leading to increased efficiency, quality of work, and overall project success.

4. Company Reputation

Construction firms that prioritize safety build a more positive reputation within the industry. A commitment to hazard prevention enhances a company’s image as a responsible and reliable partner.

Therefore, clients are more likely to choose firms with a strong safety record, leading to increased business opportunities and client satisfaction. And job candidates are more likely to want to work for a safer firm.

5. Legal Compliance

Adhering to safety regulations and actively preventing hazards ensures legal compliance. This protects construction firms from potential fines, penalties, and legal consequences, contributing to a stable and compliant operational environment.

Why Construction Firms Choose Vector Solutions

Vector Solutions brings in-depth expertise in serving the Architecture, Engineering, and Construction (AEC) industry. Understanding the unique demands and regulatory landscape of construction, our solutions are crafted to address the distinct challenges faced by construction firms, ensuring relevance and effectiveness. We offer:

- Comprehensive Safety Training. Vector Solutions offers a diverse library of safety and construction training courses. From OSHA compliance to specialized training in construction hazards, our courses are designed to address the unique risks faced by construction professionals.

- Cutting-Edge EHS Management Software. Vector EHS Management provides construction firms with the tools they need to proactively identify, assess, and mitigate hazards. With robust reporting and analytics, firms can stay ahead of safety challenges, ensuring a secure and compliant working environment.

- Accessible Learning Management System (LMS). Vector Solutions’ LMS for construction allows firms to create, deliver, and track training programs seamlessly. With a user-friendly interface, Competency Assessment tool, and robust reporting, construction companies can tailor their training initiatives to align with their specific needs and goals.

Construction firms choose Vector Solutions based on our proven track record of success. Here’s what our clients have to say:

“We are always looking for ways to help educate our construction personnel and give them the tools they need. Vector Solutions has a diverse library that we can offer to a lot of employees no matter what their role is in the company.”

— EMJ Corporation

“One thing that stands [Vector Solutions] apart from other competitors is the customer service…they’re responsive throughout the organization.”

— CHA Consulting